ZONE PICKING WITH SAT & SMART AMR

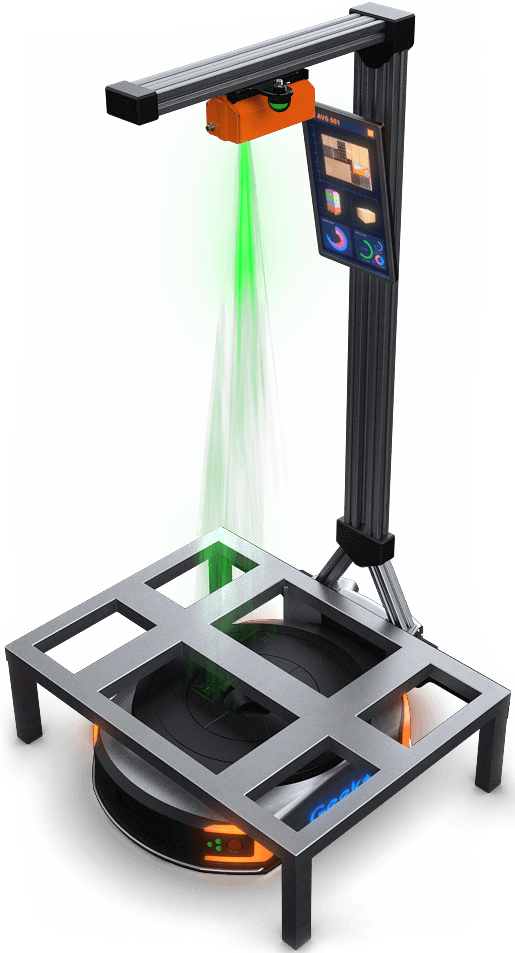

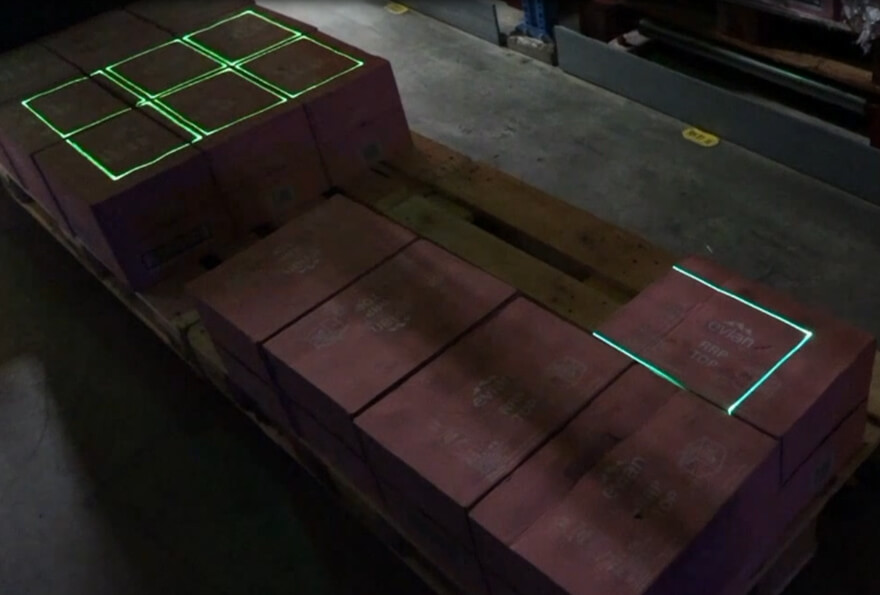

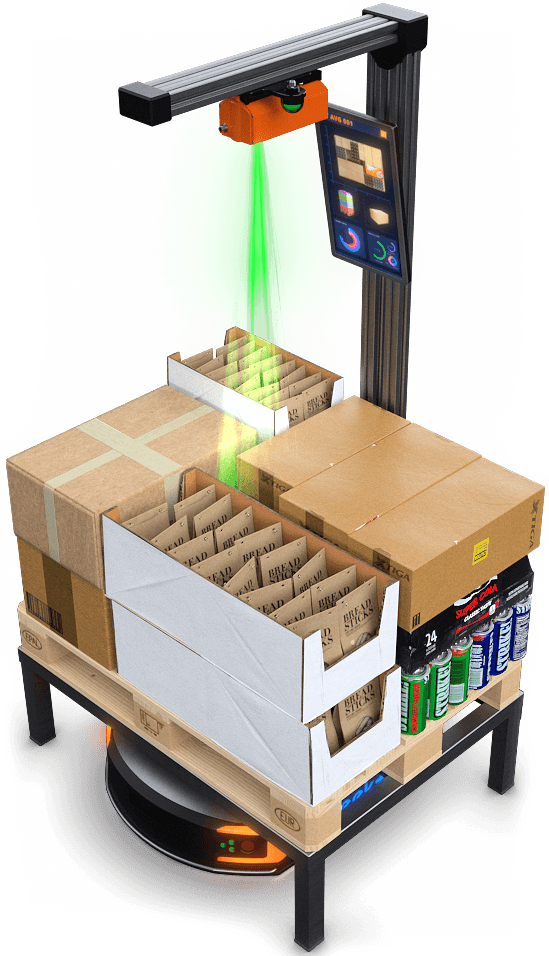

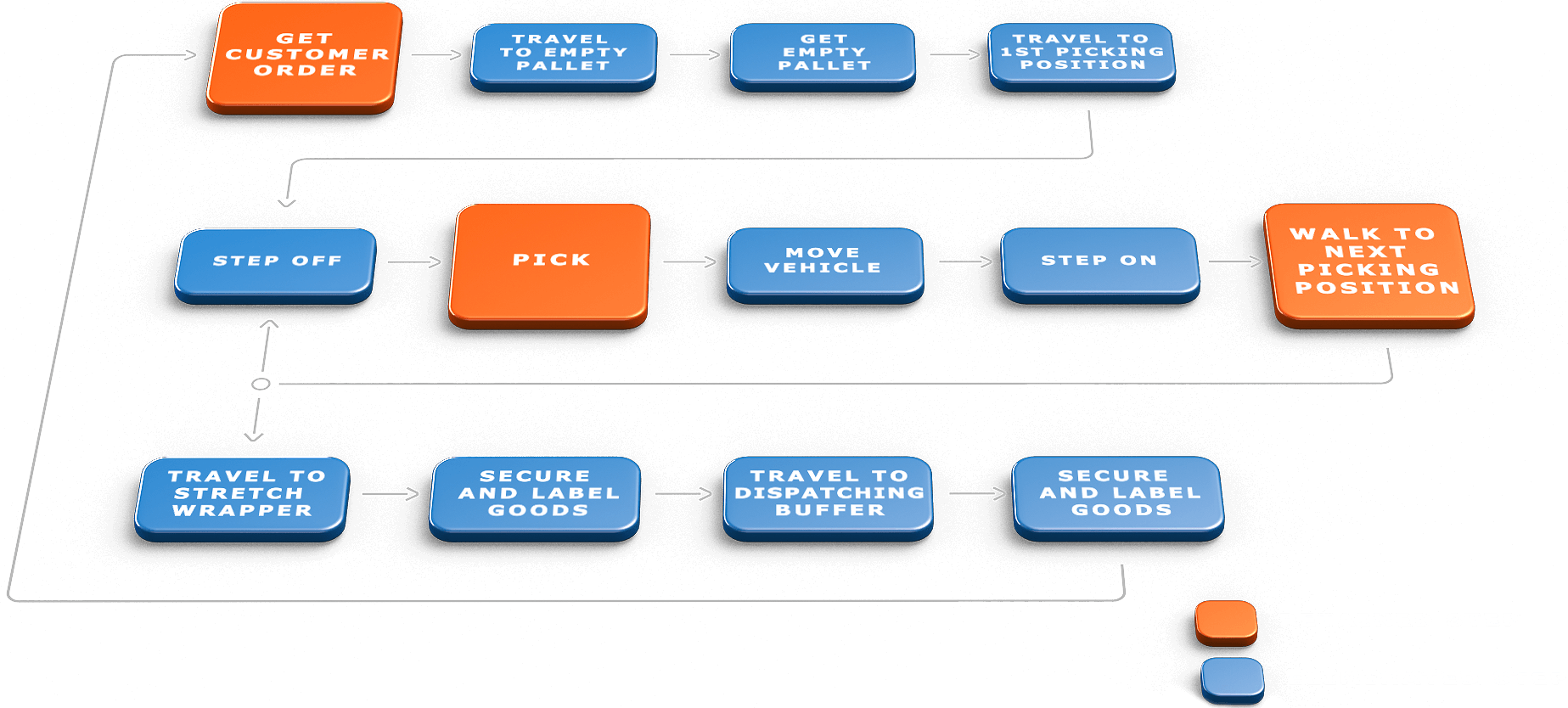

SAT ZONE PICKING combines all the advantages of the Stack Assist Tool (developed by our partner SAT Technologies) and smart AGV/AMR technology and brings a completely new way of order picking to the market. It prevents time-consuming activities such as searching, getting on and off, delivering and delivering pallets or driving around. The time saved translates into higher productivity, leading to lower operating costs.

With Smart Zone picking you avoid unproductive steps in your order picking process. This not only leads to high cost savings, but also to less risk of accidents and less risk of damage to goods.

WHY AMR’S

- Efficient picking

Efficiency 3x faster vs manual pick operation - Fast ROI

Payback time within 1-3 years - Peak management

Increase or decrease the number of robots at any time based on the order forecast - Rapid implementation

Short implementation time & Go-live within 12 weeks - Lower labor costs

Reduce labor costs and intensity by up to 70%

- Efficient use of storage space

Increase storage space efficiency by up to 30%. Multi-storey integration for high volumes and orders with multiple SKUs - Lower investment

Maintain financial liquidity with the AMR lease model - Accurate picking

Achieve 99.99% accuracy - Safer Operations

Meeting higher safety requirements - Flexible relocation

Simple and fast re-installation of robots in case of relocation of warehouse facilities

The advantages at a glance

Productivity enhancing

Reduce costs

Reduce training

Stack higher and more stable

Pick faster without mistakes

WSR SERVER

All WSR mixed palletizing solutions are equipped with the in-house developed WSR Server software suite. The WSR Server software is in fact the conductor of the entire end of line mixed palletizing system in a warehouse and communicates with the WMS/WCS of the customer and with the various mixed palletizing systems.