GRIPPERS AND MORE

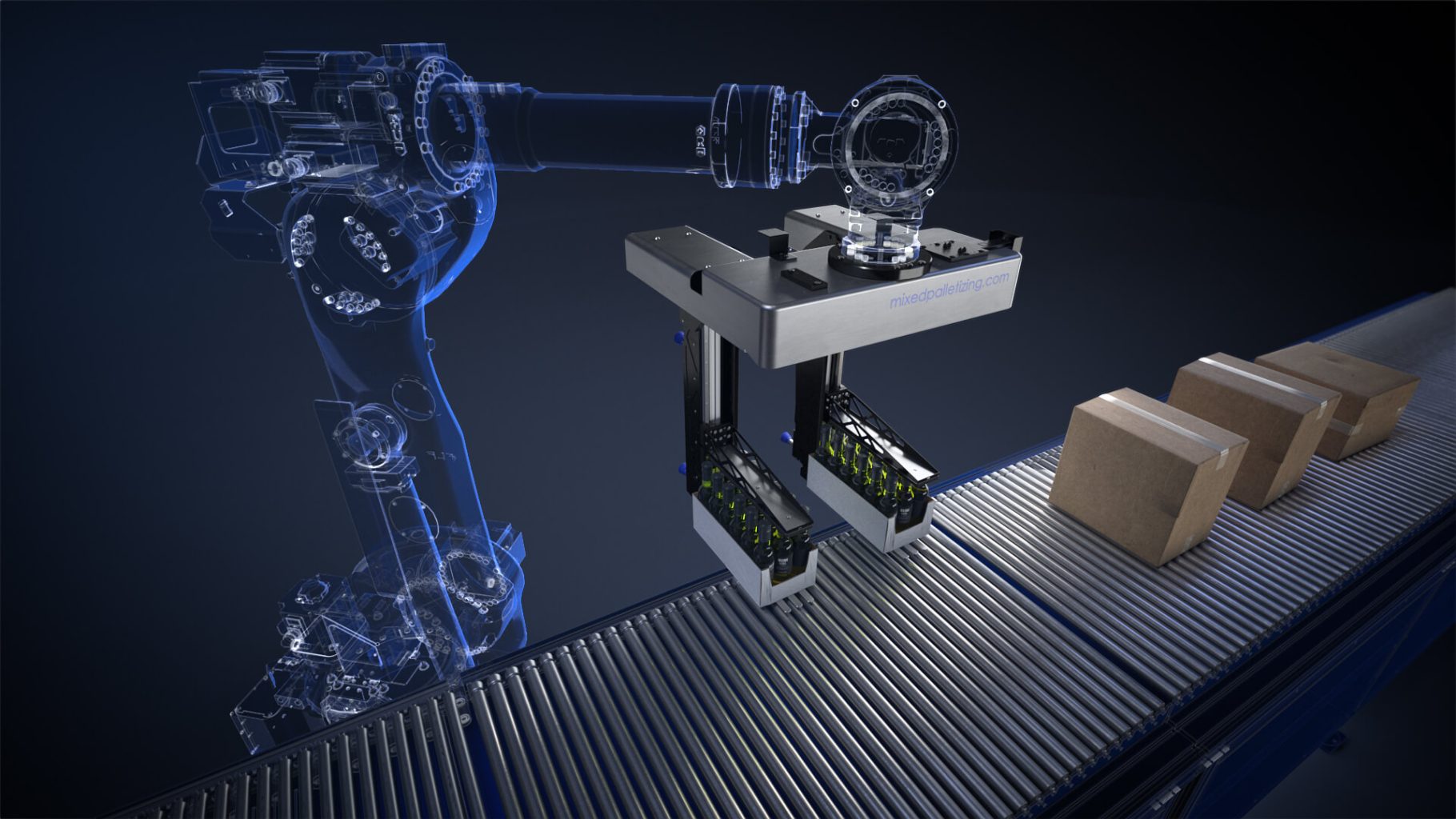

The MCS Technology combines WSR’s revolutionary, state-of-the-art adjustable MCS fork grippers, Pickup Conveyor, robotics and WSR server control system to streamline the stacking of stable pallets of mixed products in distribution centers. Real mixed pallets usually consist of uneven layers.

MCS GRIPPER SERIES

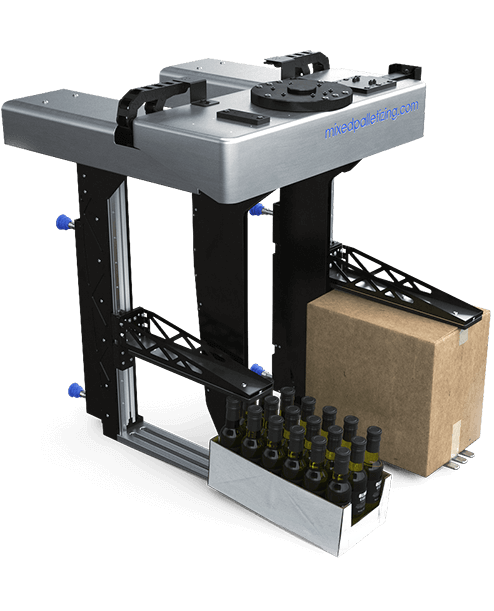

Conventional solutions for palletizing mixed products cannot pick more than one box at a time, while the MCS-2 gripper with 2 adjustable forks can stack up to two boxes at a time with great accuracy. Such an MCS-2 gripper with its single robot can process up to 960 boxes (85% Utilization) per hour, depending on the packaging type and size.

MCS-2 EOAT

- Up to 1200 CPH (2 pickup)

- Only for pallets

- No servo pneumatic controlled cylinders

MCS-2 Compact EOAT

- Up to 1200 CPH (2 pickup)

- For pallets & roll cages

- Servo pneumatic controlled cylinders

- Special designed for Twin robot stacking

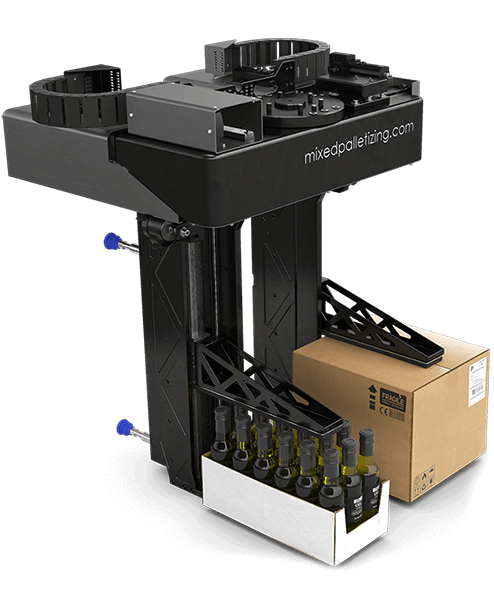

MCS-2-RP EOAT

- Up to 600 CPH (2 pickup)

- For all size pallets & roll cages

- Developed for Robo-Pick gantry applications

MCS-1-RP EOAT

- Up to 300 CPH (1 pickup)

- Max case weight: 15kg

- Developed for Cobot applications

Click on an image to enlarge it

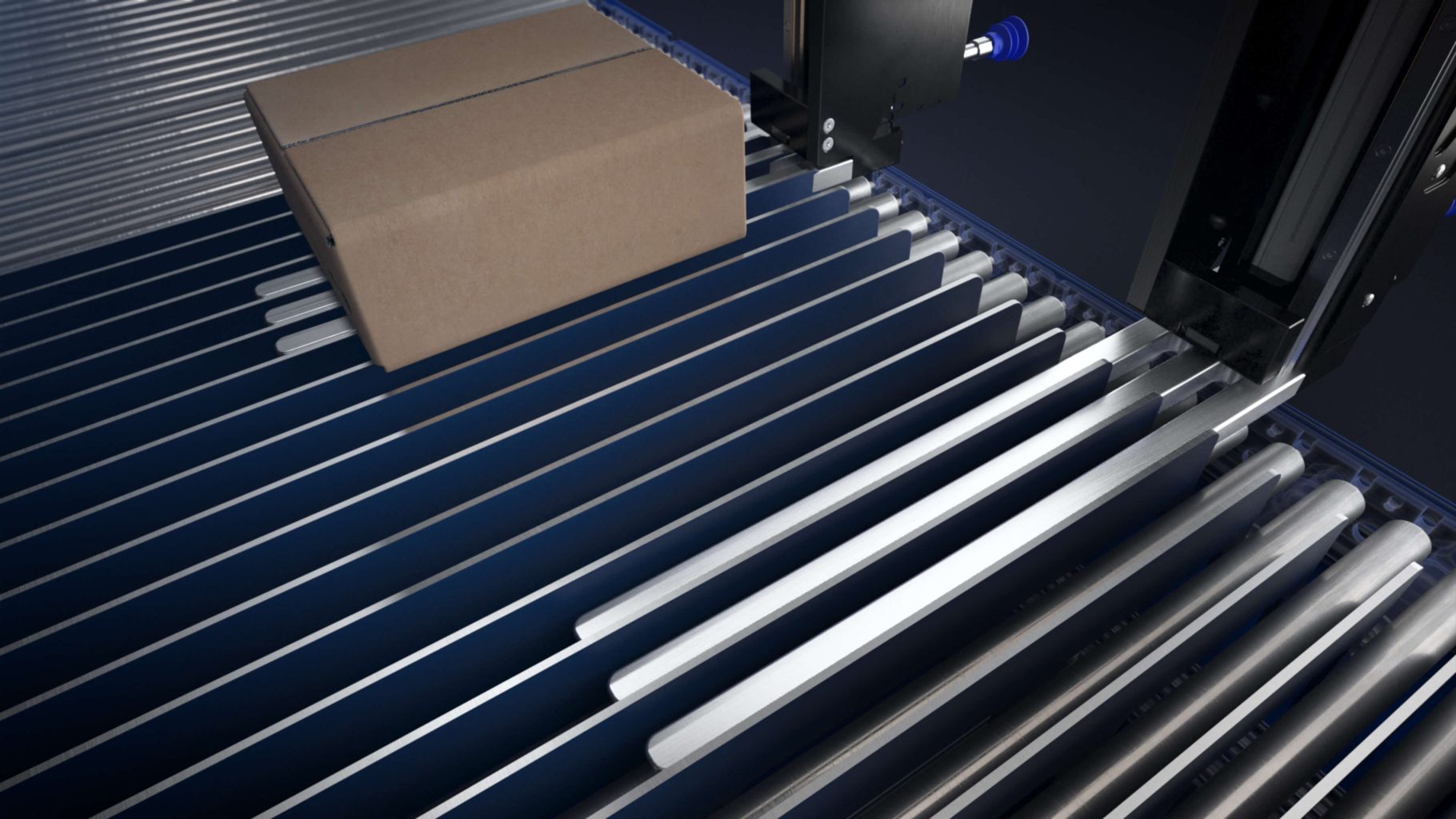

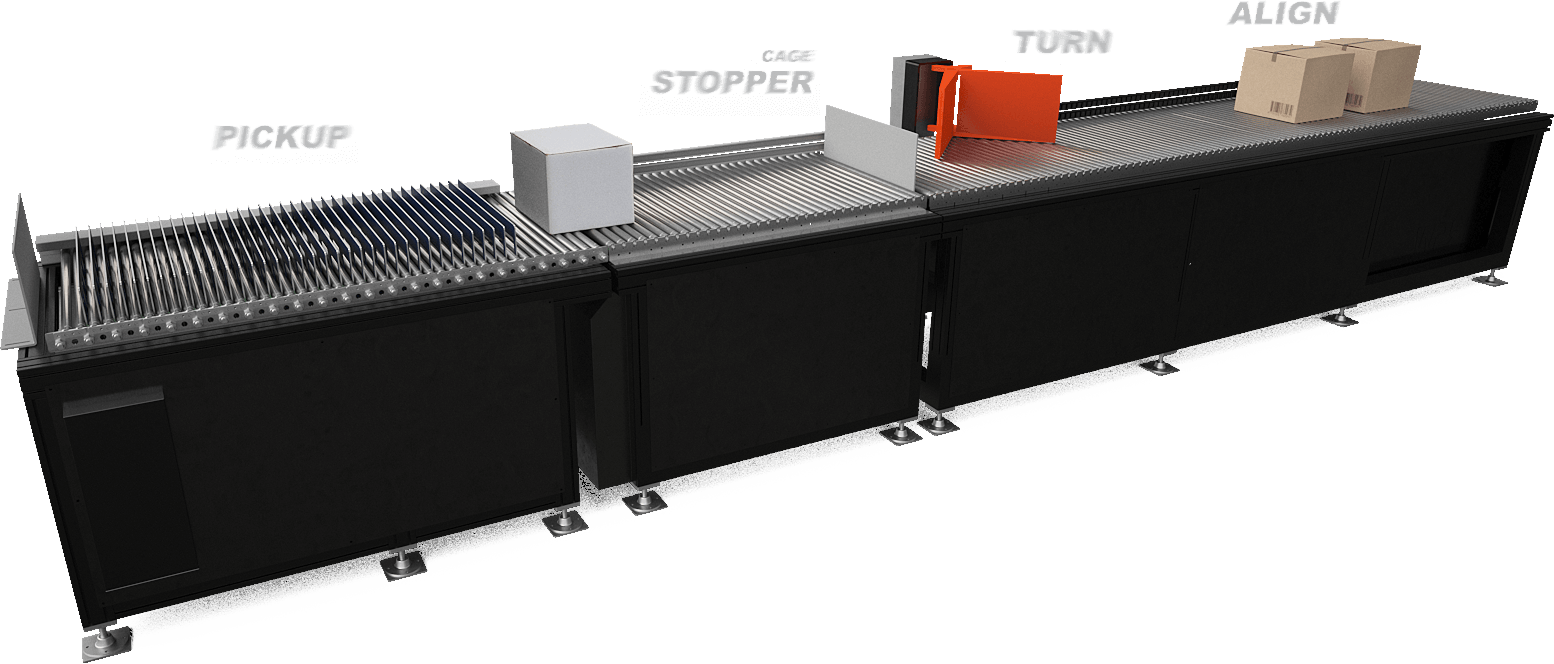

ALIGN, TURN AND PICKUP CONVEYOR

The MCS Pickup conveyor offers an optimal supply for palletizing mixed products. With the MCS Pickup Conveyor, each product is aligned, rotated, grouped and set ready to be picked with the MCS-2 gripper. The MCS Pickup conveyor is specially designed for a high capacity throughput (max. 1400 mixed cases per hour)

WSR SERVER

All WSR mixed palletizing solutions are equipped with the in-house developed WSR Server software suite. The WSR Server software is in fact the conductor of the entire end of line mixed palletizing system in a warehouse and communicates with the WMS/WCS of the customer and with the various mixed palletizing systems.