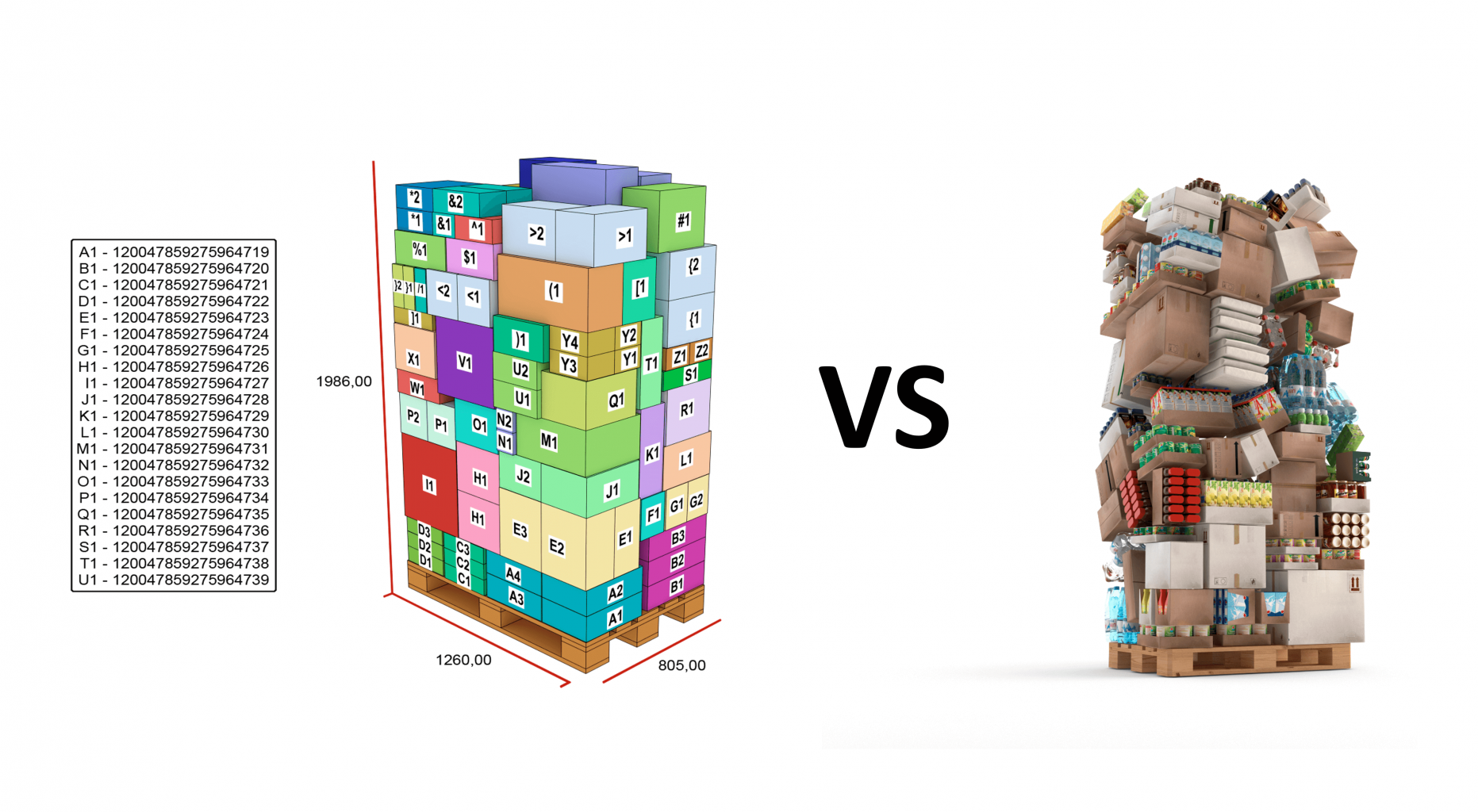

Sequenced versus on the fly mixed palletizing

The strategic advantage of in-sequence automatic mixed palletizing compared to on-the-fly mixed palletizing.

In the field of modern logistics and warehouse management, efficiency is paramount. As companies strive to streamline their operations and optimize their supply chains, the process of picking boxes and palletizing mixed boxes plays a crucial role. Traditionally, palletizing mixed boxes involved placing products on pallets in a predetermined manner, usually based on a fixed order. However, technological advances have introduced the concept of mixed palletizing ‘on-the-fly’, where products are randomly delivered and arranged on the pallet in real-time using Vision cameras and AI algorithms.

While on-the-fly mixed palletizing may seem like a breakthrough solution, there are clear benefits to the traditional approach of automated sequential mixed palletizing.

In this blog we explore why having full knowledge of the product composition in advance offers superior benefits compared to dealing with random product delivery for stacking mixed pallets.

Optimal use of space:

Sequence mixed palletizing allows precise planning of pallet layouts based on the dimensions and characteristics of each product. With prior knowledge of the products to be palletized, our mixed palletizing algorithms can calculate the most space-efficient stacking configurations, maximizing the use of available space on the pallet. This ensures that each pallet is stacked to its full capacity, reducing the need for additional trips and minimizing transportation costs.

Improved stability and security:

When products are known in advance, our mixed palletizing systems can arrange them in such a way that optimal stability during transport and storage is guaranteed. By strategically positioning products based on their weight, fragility and compatibility, the risk of pallets falling over or products being damaged is significantly reduced. This not only improves safety in the warehouse, but also minimizes the chance of product loss or spoilage during transport.

Increased throughput and efficiency:

Predictability is the key to achieving high throughput and efficiency in mixed palletizing operations. With palletizing mixed orders in sequence, warehouses can plan their workflows more effectively, because they know exactly which products need to be palletized and in what quantities. This ensures better coordination of resources, such as manpower and machines, leading to smoother operations and faster turnaround times. In contrast, on-the-fly mixed palletizing introduces variability and unpredictability, making it challenging to maintain a consistent workflow and meet tight deadlines.

Quality control and traceability:

Knowing the composition of each mixed pallet in advance enables better quality control and traceability throughout the supply chain. Palletizing sequenced orders allows companies to easily track the origin of each product, check expiration dates and ensure regulatory requirements are met. This level of visibility not only improves inventory management, but also instills confidence in customers regarding the safety and integrity of the products they receive.

Adaptability and scalability:

While palletizing sequenced orders may seem rigid at first, it offers greater adaptability and scalability in the long term. As companies expand their product offerings or enter new markets, they can easily adapt their palletizing configurations to meet changing demands. Furthermore, by using our AI and sequenced optimization algorithms in combination, we can continuously refine palletizing strategies to adapt to changing market conditions and operational requirements.

Conclusion:

Although on-the-fly mixed palletizing can be attractive in terms of flexibility and price, the strategic advantages of automatic mixed palletizing in sequence are undeniable. By having full knowledge of product composition in advance and using advanced technologies for optimization, companies can achieve greater efficiency, safety and control in their mixed palletizing operations. As the logistics landscape continues to evolve, embracing proven methodologies and technologies will be critical to staying ahead and delivering exceptional value to customers.

WSR Solutions offers both options (which one fits best depends on the situation and the chosen end of line solution).