WSR SOLUTIONS

The experts in Mixed Case Palletizing

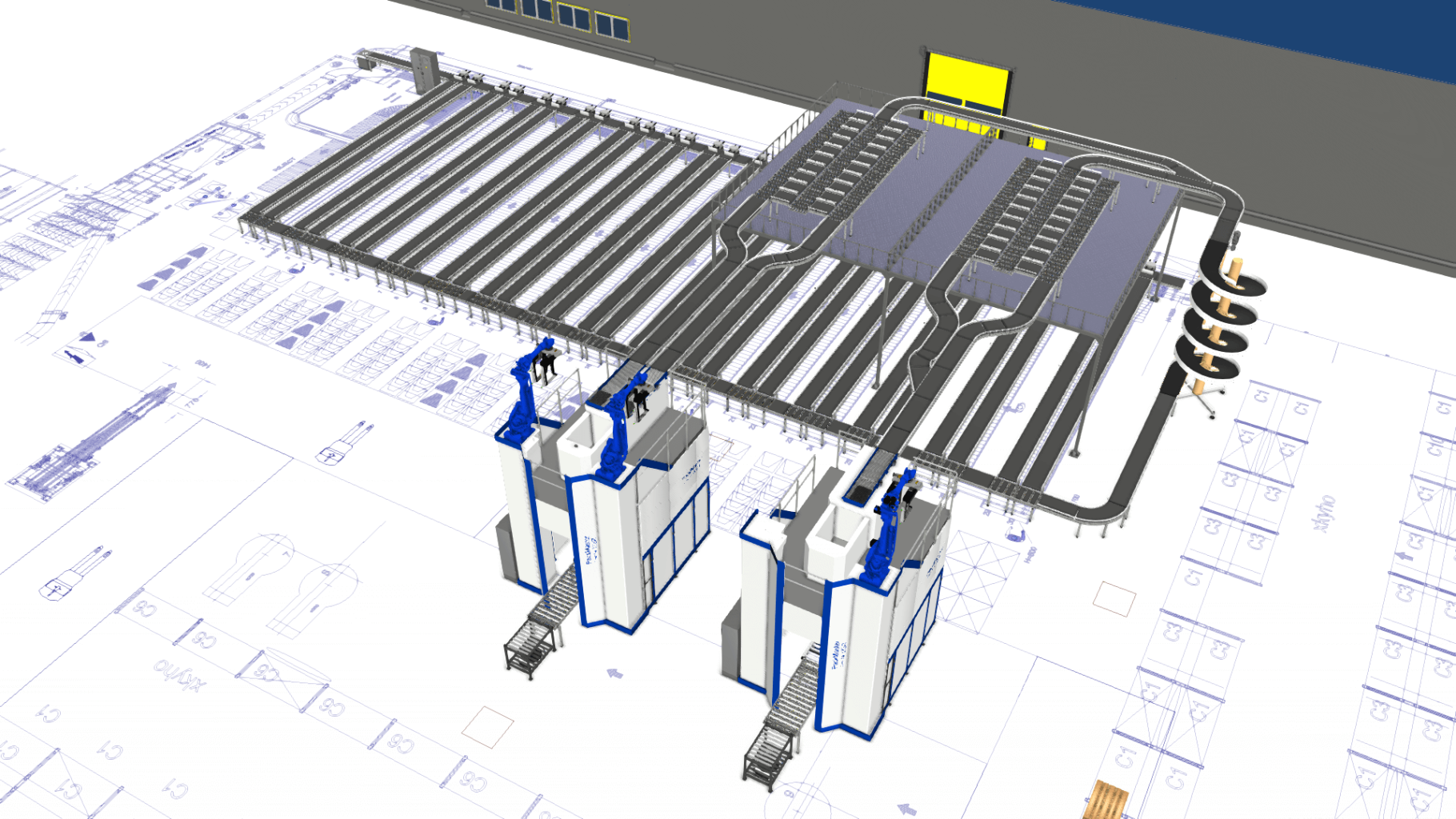

We are experts in layer de-palletizing and mixed palletizing technology for the international intralogistics market providing a complete framework for changing market requirements.

We develop and deliver optimized manual and fully automatic end of line mixed palletizing solutions (hardware and software) for both the end customer and robot/system integrators worldwide.

Events

More eventsLatest News

More news

Grippers and more

Every logistics operation is different. Check here which solution is best suited for your situation.

Optimized Mixed Palletizing

Stacking mixed pallets is challenging, especially for humans. Check here which solution is best suited for your situation.

Featured this month!

The advantages at a glance