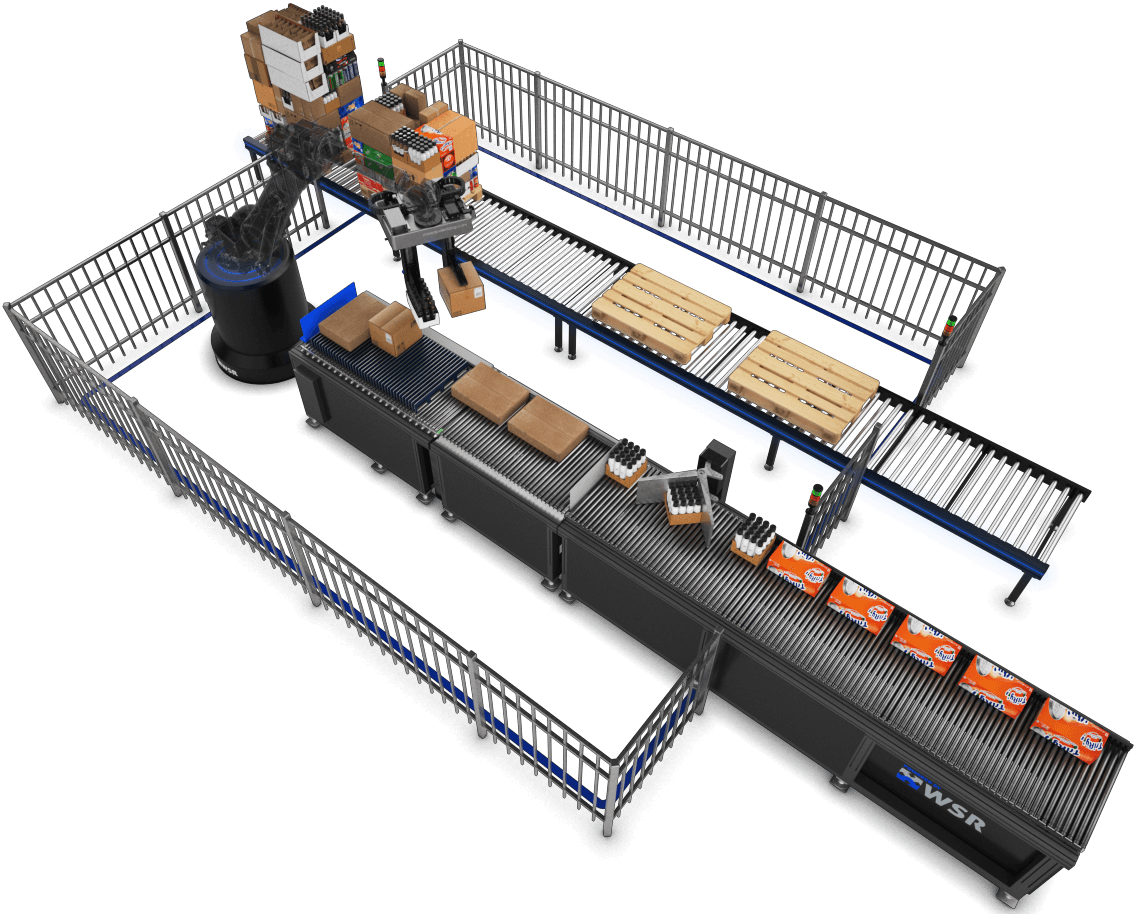

OPTIMIZED MIXED PALLETIZING

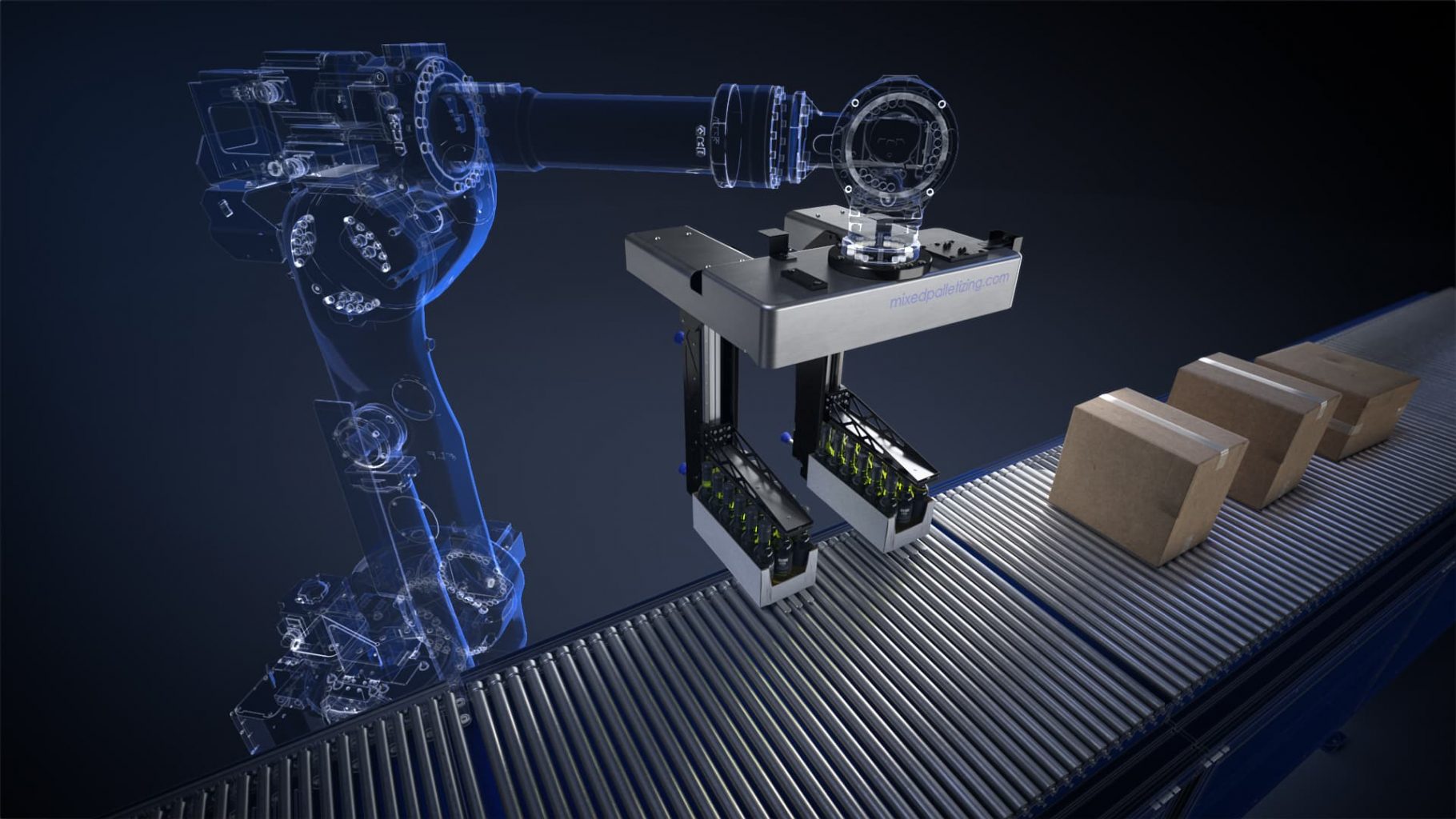

The WSR Automatic Mixed Palletizing solution is capable of handling a wide range of different types of products & packages. It can be equipped with an integrated foil wrapping unit to stabilize the mixed pallets. It is designed for high output capacity (max 1200 cases/hour) by using the high performance MCS-2 gripper which is able to pickup and place a maximum of 2 packages at once while conventional grippers can handle only one package. In contrast to standard gripper solutions, we can reach a 2 times higher output

| NR CASES PER PICKUP | 1 CASE | 2 CASES |

| Max output capacity p/hr | 600 CASES P/HR | 1200 CASES P/HR |

| Output capacity (80% utilization) | 480 CASES P/HR | 960 CASES P/HR |

i-PACKSTATION

Our end-of-line mixed palletizing solutions are designed for continuous use. In manual or automatic operation, they achieve a substantial reduction of ergonomically challenging work (health & safety) and therefore labor costs. The innovative design of the i-Packstation combines operational ergonomics, efficiency and cost effectiveness.

WSR SERVER

All WSR mixed palletizing solutions are equipped with the in-house developed WSR Server software suite. The WSR Server software is in fact the conductor of the entire end of line mixed palletizing system in a warehouse and communicates with the WMS/WCS of the customer and with the various mixed palletizing systems.